From design to delivery, we provide comprehensive plastics fabrication services tailored to meet the unique needs of your project.

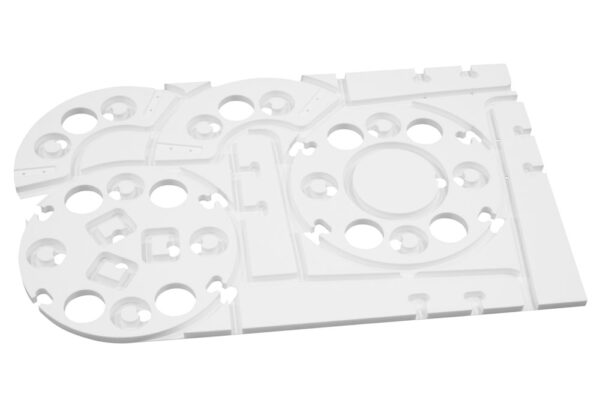

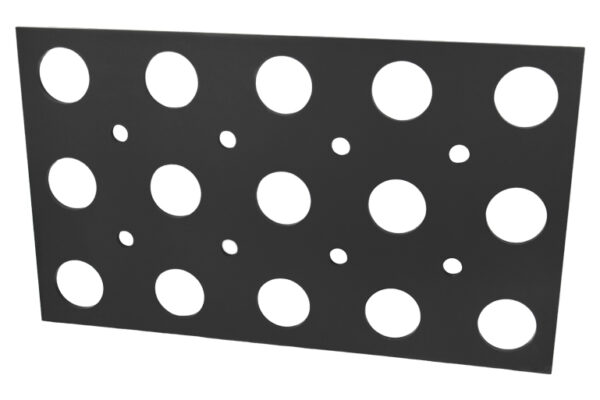

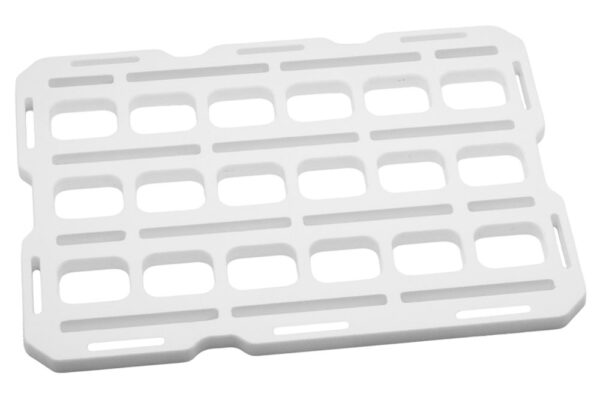

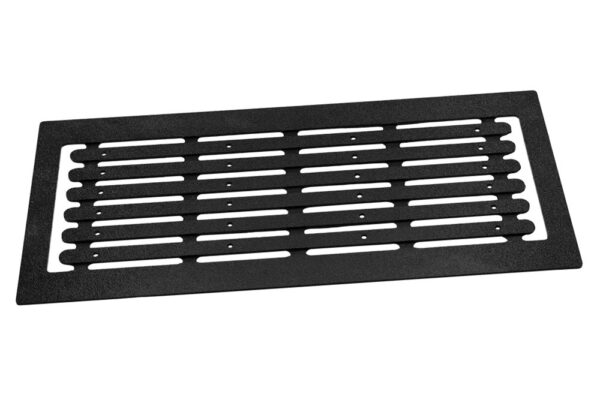

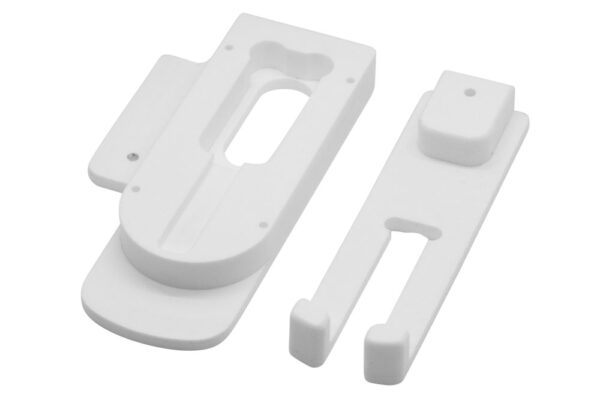

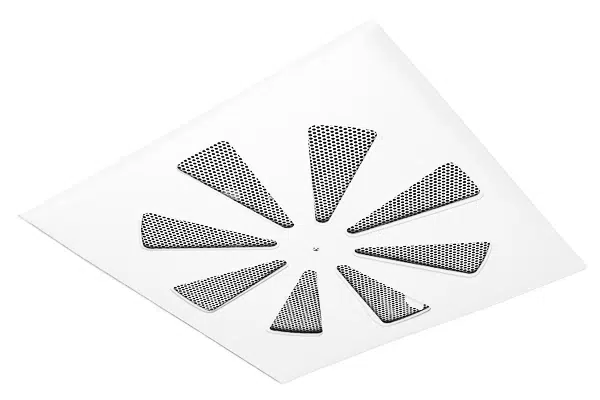

Our Plastic Fabrication Capabilities

At Teak Isle, we offer a full range of plastic fabrication services, including CNC machining, laser cutting, thermoforming, and more. Our 300+ person production team offers comprehensive secondary assembly services. From assembling multi-part components to adding finishing touches like hardware installation and polishing, we ensure every piece meets your exact requirements. Our experienced sales and engineering team offers value-focused consultation services – making sure you get the best part at the best price.

Learn More About Specific Plastics Fabrication Techniques

Our Wide Selection of Plastic Materials

At Teak Isle, we work with a wide range of high-quality plastics to meet the needs of any project. From durable HDPE for outdoor and marine applications to acrylics for clear, polished finishes, we offer materials that suit various industries. We also specialize in ABS, PVC, and UHMW for strong, impact-resistant parts. Whether you need lightweight options, UV stability, or custom colors, our team will help you choose the best material to ensure your part performs perfectly in its environment.

- HDPE

- Acrylic

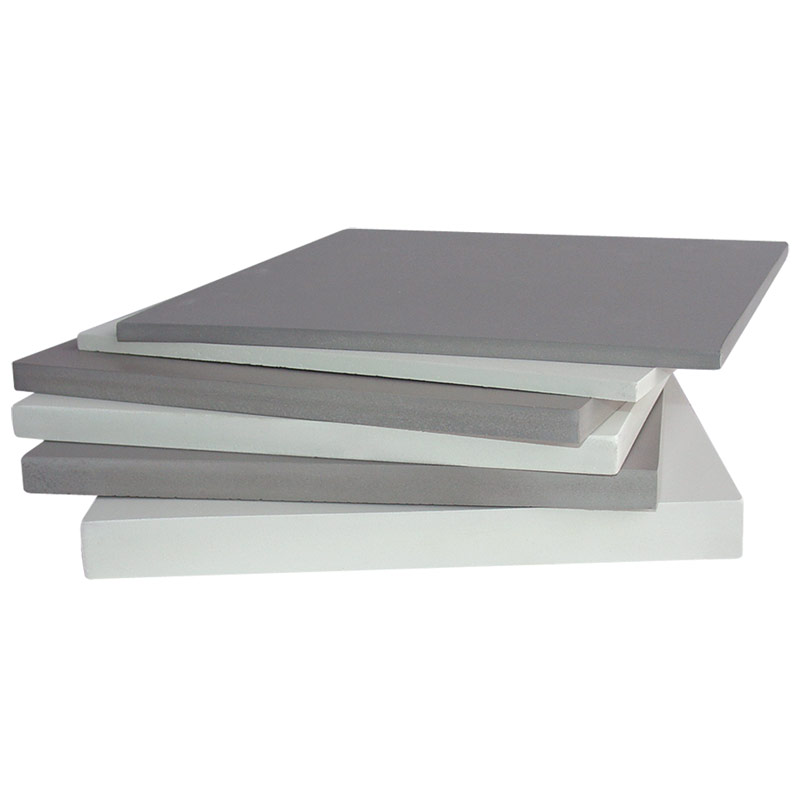

- Expanded PVC

- Reinforced Polyurethane

- Laminated Honeycomb PP

- Flexible Vinyl

- EVA Foam

- Composite Lumber

- Solid Surface

- High Pressure Laminate

- Plywood

- MDF

- ABS

- Polycarbonate

- ACM

- Phenolic

- UHMW

- Aluminum

- Steel

HDPE

Durable, weatherproof, and corrosion-resistant. Popular for outdoor furniture and marine accessories.

- Marine and boat components

- Outdoor furniture and playground equipment

- Cutting boards and food prep surfaces

- Exterior signage and displays

- Material handling and wear strips

Acrylic

Versatile plastic (available clear, tinted or opaque) commonly used for signage, displays, and protective barriers.

- Signage and displays

- Protective barriers and shields

- Aquariums and fish tanks

- Picture frames and photo displays

- Point-of-purchase displays and retail fixtures

Expanded PVC

Lightweight and easy to fabricate. Great for substrates, signage and lightweight displays.

- Upholstery Substrate

- Signage for indoor and outdoor use

- Exhibit and display setups

- Thermoforming projects

Reinforced Polyurethane

High-density foam composite, lightweight yet strong, ideal for marine and industrial applications.

- Marine decking and flooring

- Boat transoms and bulkheads

- RV and camper construction

- Architectural elements in buildings

- Industrial and transportation components

Laminated Honeycomb PP

Lightweight, rigid honeycomb panel, engineered for a range of structural applications.

- Decks and bulkheads in marine manufacturing

- RV floors, walls, and ceilings for weight reduction

- Lightweight structural components in rail and aerospace

- Partitions, walls, roofing, and floors in construction

Flexible Vinyl

Durable, waterproof material for flooring, signage, and upholstery, offering easy maintenance.

- Healthcare facilities for hygiene and durability

- Educational institutions for easy maintenance

- Retail spaces for aesthetic versatility

- Marine environments; water-resistant qualities

- Office buildings for cost-effective flooring

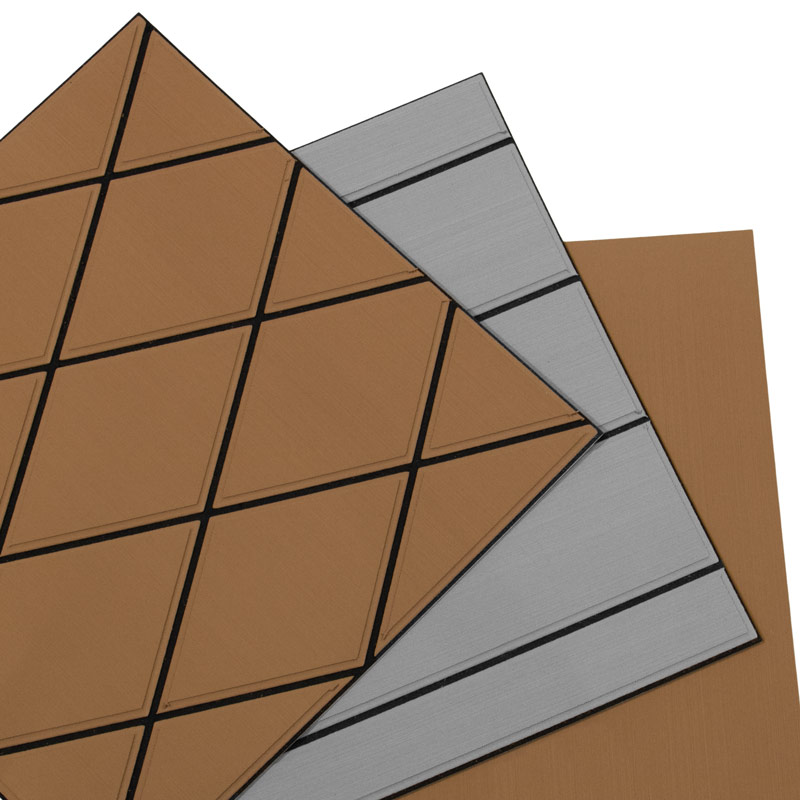

EVA Foam

Attractive, non-slip foam sheets provide comfort, safety, and traction.

- Custom boat decking for comfort and aesthetics

- Shelf liners; provide cushioned surface and keep items from sliding

- Step pads for comfort and traction in high-traffic areas

- Shower seats for a soft non-slip surface

Composite Lumber

Mimics real wood grain, maintenance-free. Perfect for attractive, weather-resistant outdoor furniture.

- Outdoor furniture and playground structures

- Marine docks and boardwalks

- Pergolas and arbors

- Raised garden beds

Solid Surface

Seamless and non-porous; ideal for custom countertops, commercial environments and healthcare surfaces.

- Kitchen countertops and backsplashes

- Bathroom vanities and shower surrounds

- Healthcare and dental office surfaces

- Food service counters and tabletops

- Reception desks and office furnishings

- Wall panels and interior cladding

High-Pressure Laminate

Decorative, available in many designs. Easy to clean and maintain; excellent for high-use areas like schools and offices.

- Cabinet surfaces and doors

- Commercial and residential countertops

- Decorative interior surfaces

- Restroom partitions and lockers

Plywood

Cost-efficient, multi-use material. Great for templates, jigs and budget friendly structural projects.

- Fixtures, jigs, and templates

- Structural underlayment

- Construction framing and sheathing

- Factory work tables and furniture

MDF

Consistent density and strength. Smooth surface, easy to paint. Ideal for detailed moldings and millwork.

- Interior carpentry, shelving and furniture building

- Decorative wall panels and wainscoting

- Door and window frames

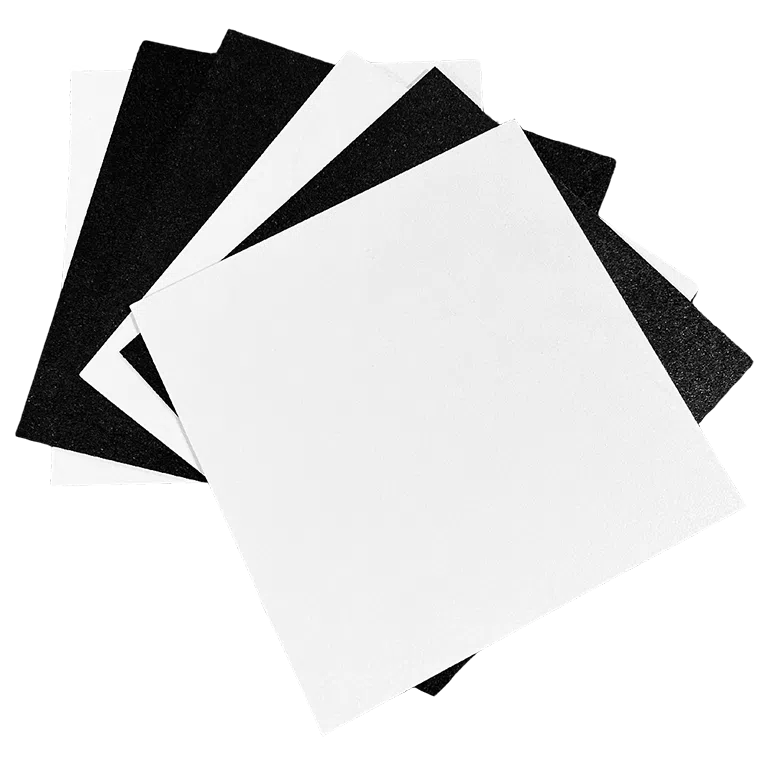

ABS

Cost-effective, thermoformable polymer with a glossy exterior and low moisture absorption.

- Protective casings and electrical enclosures

- Durable signage and point of purchase displays

- Interior automotive panels and trim

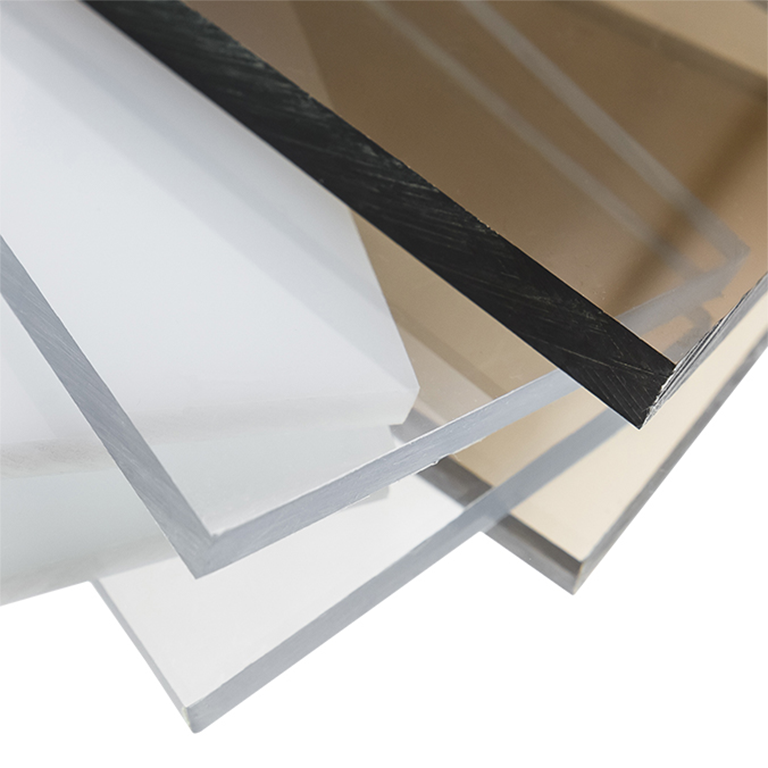

Polycarbonate

A strong, transparent, or opaque plastic, known for its high impact resistance and versatility.

- Machine guards in industrial settings for clear visibility and safety

- Eyewear lenses due to high impact resistance and clarity

- Roofing materials for light transmission and strength

- Bulletproof glass for security in vehicles and buildings

- Automotive components like headlight covers and sunroofs

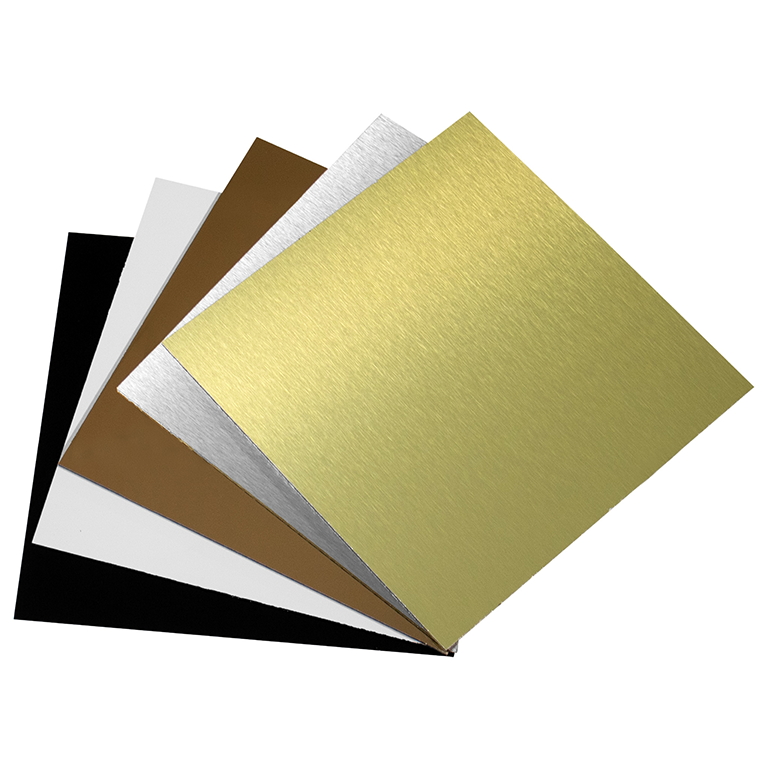

ACM

A durable panel with two metal sheets bonded to a non-metal core, ideal for building cladding and signage.

- Exterior building cladding for commercial and residential structures

- Signage and advertising panels for outdoor and indoor use

- Interior wall panels and partitions in commercial spaces

- Column covers and beam wraps to enhance architectural design

- Vehicle and trailer bodies for lightweight and durable construction

Phenolic

Compact industrial reinforced laminate. Lightweight yet tough — half the weight of aluminum with superior abrasion and impact resistance.

- Backing plate coring material

- Electrical insulators and circuit board substrates

- High-stress mechanical parts such as gears and bearings

- Industrial laminates for harsh environments

UHMW

Exceptionally durable with high impact strength and low friction; ideal for wear-resistant parts and lining systems.

- Wear strips and slide guides for machinery

- Impact-resistant parts for industrial equipment

- Chute, hopper, and bin liners for material handling

- Bottle and can line machinery components

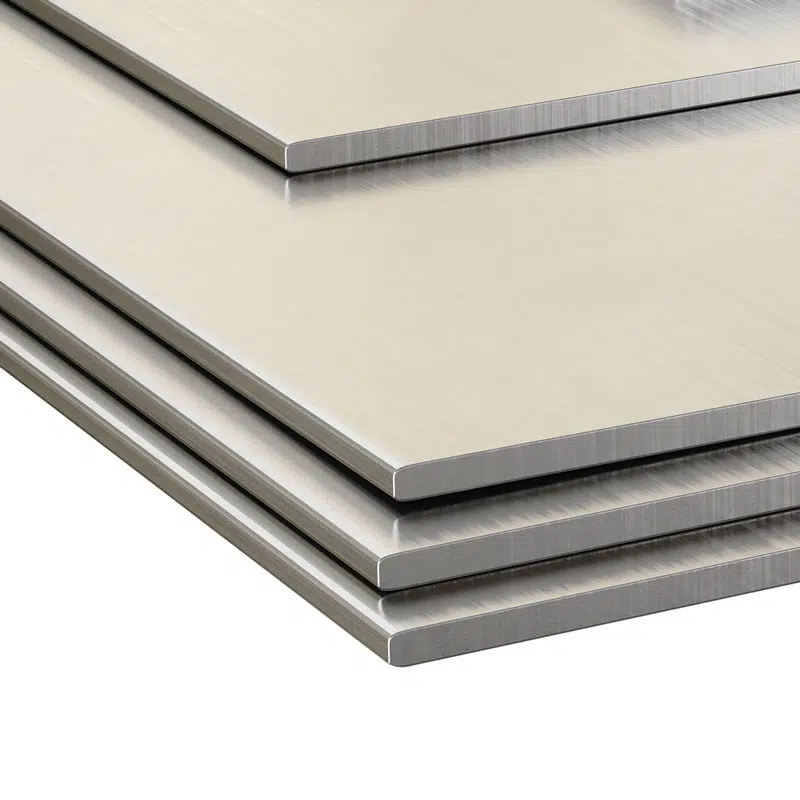

Aluminum

Lightweight and strong; up to 3x lighter than steel. Naturally corrosion-resistant; superior for marine and outdoor applications.

- Door frames for their lightweight and strength

- Marine hardware and fittings resistant to corrosion

- Custom machinery components

Steel

Cost effective metal (generally less expensive than aluminum) with higher strength and durability.

- Structural components in construction for robust support

- Heavy machinery parts due to high strength and durability

- Automotive frames and chassis components for toughness

- Tools and dies for precision machining and forming

Gallery of Plastics Fabrication & Manufacturing

Customer Success Stories

Teak Isle’s Low MOQs Helps HCB Yachts Offer the Customization Options Their Customers Demand

How Teak Isle Helps Godfrey Marine Turn Vision Into Reality and Improve Customers Time on the Water

An Extraordinary Commitment to Customer Service Drives Teak Isle’s Relationship with Everglades Boats

Trusted by Leading Companies

What they're saying...

Hear from our customers, and find out why Teak Isle is the best.

Send us a Message

After hours or prefer to schedule a call? No problem.

Send us a message and we’ll jump right on it.

Call Us Now

Need a partner you can trust to deliver quality on-time parts?

Pick up the phone and chat with a team member now.

(833) 522-5090

Mon-Fri 8am – 4pm (EST)

Plastics Fabrication FAQ

What is the typical lead time for fabricating custom plastic components?

Lead times for custom plastic parts depend on whether you’re in the prototype or production phase. Prototype lead times vary based on part complexity: simple 2D shapes can take 1-3 days, while more complex bent parts may take 3+ weeks. Our sales team will provide more specific estimates for your design and will always do everything possible to accommodate your specific requirements.

For ongoing production of approved parts, we typically maintain a 3-week lead time. This allows us to schedule production jobs across our large customer base while maintaining a high on-time shipping rate.

What if I don’t know what material is best for my application?

If you’re unsure which material is best for your project, our experienced sales and engineering teams are here to help! We’ll assess your project’s requirements and recommend materials that will meet your goals—whether that’s durability, strength, or environmental resistance.

We focus on value engineering, designing the most cost-effective part possible to achieve your goals. Material selection, thickness, and yield are major cost drivers, and speaking with us early in the design process can help ensure you choose the best material without sacrificing quality or performance.

Are there limitations on shapes and sizes that can be fabricated from plastic?

Almost any shape or size part can be fabricated from plastic. That said, different manufacturing techniques and materials have specific limitations. For example, when CNC cutting material from sheets, you are limited by the maximum sheet sizes. When thermoforming plastics, you are limited by their flexibility and bend radius.

Our team is always available to provide free feedback on manufacturability. Whether you need guidance on material capabilities or design adjustments, our sales and engineering teams are happy to help you find the best solution for your project.

What types of plastics are best for outdoor or high-stress environments?

With our extensive experience in plastics fabrication for the marine industry, we specialize in materials designed to withstand harsh outdoor environments. HDPE, specifically King Starboard, is our top choice for these applications due to its UV stability and durability, making it ideal for boats and other outdoor projects.

Beyond HDPE, other materials like expanded PVC, acrylic, and solid surface also perform well outdoors. If you’re unsure which material is right for your project, our team is here to help you find the perfect fit.

Can plastic parts be finished with textures, colors or coatings?

It depends entirely on the material selection and manufacturing technique. Some plastics, like acrylic or expanded PVC, accept paint and coatings beautifully, offering a wide range of textures and colors. However, materials like HDPE or UHMW cannot be painted due to their surface properties. If you’re looking for a specific finish, our team can help guide you toward the right material to ensure you achieve the desired look and functionality for your project.

How much does plastic fabrication cost?

The cost of plastic fabrication varies widely depending on the complexity of the part and the quantity being produced. To help manage pricing, we provide free quotes and focus on value engineering. This means we work closely with you to optimize material selection, part size, and design for manufacturability—ensuring your project is both cost-effective and efficient to produce.

By involving our team early in the design process, we can suggest materials that balance performance with price and ensure the design maximizes material yield, reducing waste. Every step we take is focused on getting you the best quality part at the best possible price, with no unnecessary expenses.