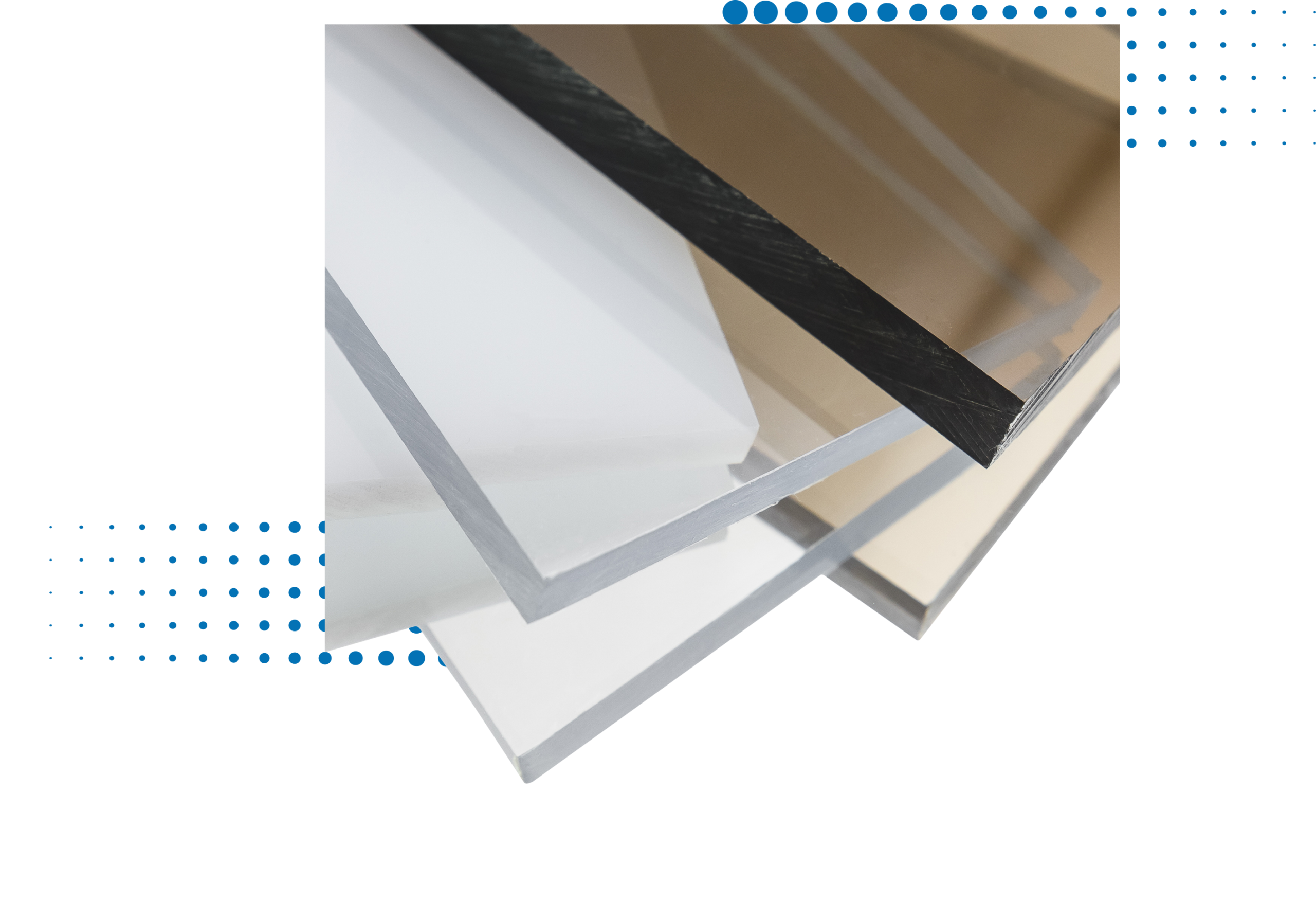

A strong, transparent, or opaque plastic, known for its high impact resistance and versatility.

Our Polycarbonate Fabrication Services

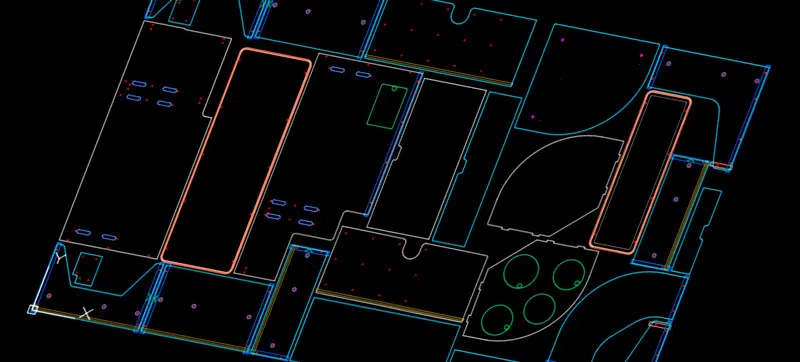

CNC machining is one of the most commonly used production manufacturing processes for creating complex, customizable, highly precise, and scalable parts. At Teak Isle, CNC machining is a foundational core competency with 12 state of the art CNC routers. We have the infrastructure and experience to produce high-quality, custom components CNC cut to your specific needs.

Polycarbonate CNC Engineering

Our engineering team uses advanced nesting software to optimize sheet yield and determine the most cost-effective order multiples.

Polycarbonate CNC Milling

We run 12 heavy-duty 3-axis CNC routers — guaranteeing quality accurate machined parts at the scale your business needs.

Polycarbonate Finishing & Assembly

Post CNC Machining, we provide edge-routing, polishing, and assembly services to provide you with a ready-to-use finished part.

Polycarbonate Fabrication 101

Advantages

- Exceptionally high impact resistance (200x stronger than glass)

- Transparent material allows for excellent optical clarity

- Lightweight (6x lighter than glass) makes it easy to handle and install

- Resistant to temperature variations without changing shape

- Can be easily molded and shaped

Limitations

- Higher cost compared to other plastics like acrylic

- Susceptible to scratches and can require special coatings

- Can yellow over time if exposed to UV light without protection

- Not resistant to solvents and cleaners, which can cause damage

Common Applications

- Machine guards in industrial settings for clear visibility and safety

- Eyewear lenses due to high impact resistance and clarity

- Roofing materials for light transmission and strength

- Bulletproof glass for security in vehicles and buildings

- Automotive components like headlight covers and sunroofs

Tradenames/Popular Brands

Tuffak, Palsun

Sheet Thicknesses

.03″ – 4″

Common Sheet Sizes

48″ x 96″

Customer Success Stories

Teak Isle’s Low MOQs Helps HCB Yachts Offer the Customization Options Their Customers Demand

How Teak Isle Helps Godfrey Marine Turn Vision Into Reality and Improve Customers Time on the Water

An Extraordinary Commitment to Customer Service Drives Teak Isle’s Relationship with Everglades Boats

What they're saying...

Hear from our customers, and find out why Teak Isle is the best.

Send us a Message

After hours or prefer to schedule a call? No problem.

Send us a message and we’ll jump right on it.

Call Us Now

Need a partner you can trust to deliver quality on-time parts?

Pick up the phone and chat with a team member now.

(833) 522-5090

Mon-Fri 8am – 4pm (EST)